Elevate Packaging Elegance with Hot Stamping - Tips

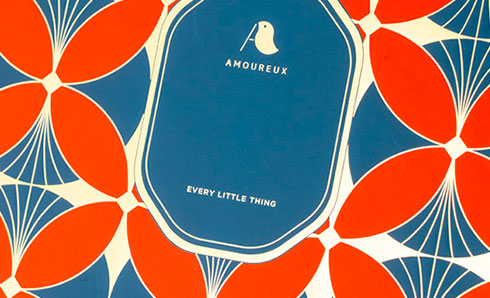

Hot stamping, a meticulous and fascinating technique, can elevate packaging quality and visual appeal, leaving a lasting impression on consumers. Consider incorporating this craft into your packaging design for enhanced effect!

To stand out in a crowded market, distinctive packaging design is indispensable. Today, let’s explore a tip to enhance the refinement and intricacy of your packaging: post-printing process Hot Stamping.

● What is Hot Stamping?

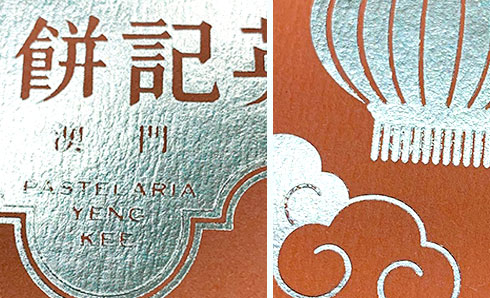

Hot Stamping is a decorative technique that utilizes the principle of heat transfer. Using a hot stamping die (typically zinc), this technique applies heated metallic foil onto the surface of print materials, creating a shiny, metallic effect. It’s a common post-printing technique in packaging design, enhancing visual impact and texture. Costs are calculated based on the stamping area.

● What Color Options are Available

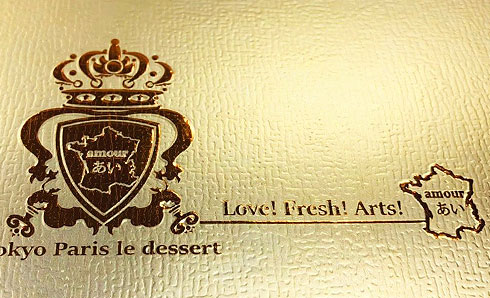

Gold and Silver: Widely used for their luxurious and noble (gold) or calm and technological (silver) effects.

Bronze: Offers a warm, classic feel, highlighting traditional brand values.

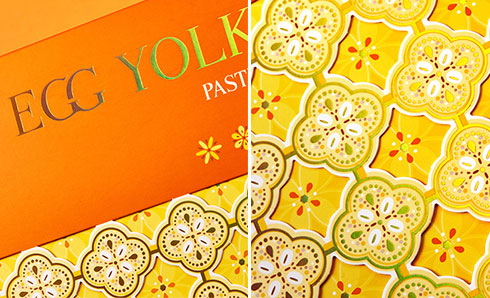

Rose Gold : Gaining popularity for its fashionable, romantic ambiance, ideal for female-centric products.

Specialty Colors: Beyond standard metallics, options include red gold, blue gold, green gold, purple gold, etc.

Unique Effects : Metallic isn’t the only option; clear foils, pearl foils (creating different effects when overlaid with printing), laser foils, and kaleidoscope effects can also diversify packaging aesthetics.

※ Actual colors should be based on hot stamping samples.

● Hot Stamping Considerations?

-

Design Aspects: Choose elements suitable for hot stamping. Complex, detailed alignment may affect the result. Very small or fine designs may lead to breaks or smudging, so assess based on actual drafts.

- Paper Choice: Opt for smooth, porous paper; lack of pores can cause bubbling or blotching due to trapped heat.

- Tolerance: Hot stamping involves a 1-2mm margin of error. If precise alignment with patterns is needed, this may affect accuracy.

These suggestions ensure optimal hot stamping outcomes!