Enhancing Packaging with Embossing Techniques - Embossing and Debossing

Feeling like your packaging is missing something? Transform ordinary 2D images into striking 3D visuals, converting smooth surface textures into dimensional layers, showcasing the unique beauty of craftsmanship.

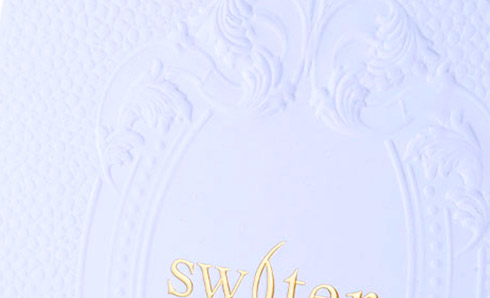

Using embossing techniques to create raised or recessed patterns on paper, provides a strong three-dimensional visual effect and a pleasing tactile sensation. Typically paired with minimalist designs or special paper materials, embossing highlights the relief effect, enhancing the overall texture.

● What is Embossing?

● What is Debossing?

Embossing involves applying pressure to paper onto a relief plate, creating a raised pattern on the otherwise flat surface, and enhancing visual and tactile focal points.

● What is Debossing?

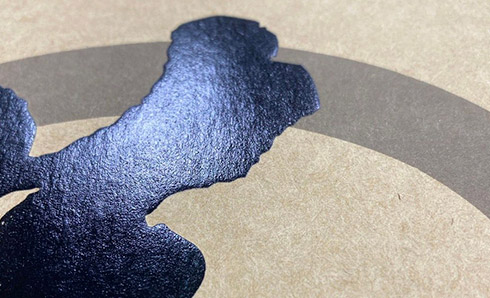

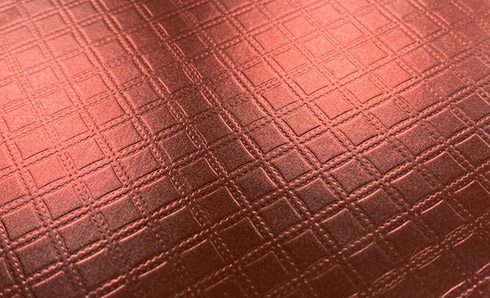

Debossing utilizes molds with recessed patterns, applying pressure to the paper to create textures, enhancing the material's quality. Different patterns offer varied expressions, infusing the paper with unique vitality. Employing debossing as an alternative to art paper is the most economical approach. However, debossing typically utilizes pre-existing patterns. For custom patterns, a unique mold can be designed for exclusive results.

● Differences between Embossing and Debossing

Embossing highlights the visual and tactile focal points of the theme, while debossing elevates the material's "texture." Particularly, using "simulated" patterns imparts different vitality to the paper, such as wood grain, stone texture, leather texture, or fabric texture.

● Considerations during Design

After embossing, the front surface will be raised, while the back surface will be recessed. Therefore, during design, texts on both sides need to avoid embossed areas, as letters or patterns in embossed areas may deform along the relief, making them less legible.

● Considerations in Material Selection

The thickness and density of the paper affect the depth of the indentation. Thicker, softer paper allows for deeper indentations, while thinner, harder paper may have difficulty producing prominent indentations. The embossing process involves applying pressure to the paper, so it is recommended to use paper with a thickness of about 240 pounds to 400 pounds (thinner or thicker paper can also be used, with machine pressure adjusted accordingly). Smooth, premium cardstock or art paper with pores, such as kraft paper, ivory cardstock, or cotton cardstock, are all excellent choices.